Why incorporate CAD/CAM digital design into your practice?

If you are considering the use of CAD/CAM digital design in your dental practice, this article will help you address many questions.

CAD/CAM digital design has had a significant impact on modern dentistry, allowing dentists to create precise and customized dental restorations with unprecedented efficiency and speed, thanks to computer programs’ assistance. Hence its acronym in English, which means Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM).

How does the new digital dentistry work? To explain simply, CAD/CAM digital design is a combination of design software and specialized hardware to create customized dental prostheses. The process begins with the use of a high-precision intraoral scanner that allows obtaining a three-dimensional image of the patient’s mouth, both of the dental pieces and the gums.

Once the digital image has been obtained, specialized design software is used to create a three-dimensional digital model of the dental restoration, allowing professionals to create a prosthesis with millimeter precision, guaranteeing a perfect fit to the patient’s reality. At this point, digital dentistry allows for closer ties between people who come to the dentist. Not only because technology virtually reduces errors to zero, facilitating treatment, but also because dentists can involve the patient in the entire process, enhancing transparency and trust.

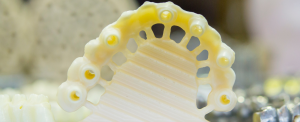

Once the model has been created, specialized manufacturing hardware is used to create the prosthesis. This technology uses a variety of techniques such as high-speed milling and 3D printing, delivering high-quality results in a shorter time.

Why are we facing an evolution of the practice? CAD/CAM digital design is especially useful in creating dental restorations such as crowns, bridges, veneers, surgical guides, occlusal planes, among others.

Regardless of the provision, dentists and dental lab technicians can rely on a substantial increase in productivity and a decrease in consultation times. That is, in a shorter period, perfect results are achieved, with direct positive effects on the patient’s quality of life. In contrast, traditional processes for creating dental prostheses can take several days or even weeks, which also multiplies the possibility of inconveniences during prosthesis creation or treatment, generating unnecessary economic and emotional wear and tear for both parties.

In summary, we leave you with 10 reasons to incorporate yourself into the digital flow:

- Improved precision and accuracy

- Reduced manufacturing time

- Customized dental prostheses

- Less traumatic for patients

- Efficient collaboration with 3D teams

- Immediate visual solutions for patients

- Digital storage and sharing of designs

- Consistency and repeatability in manufacturing

- Reduced errors

- More efficient use of materials.

Do you need advice on these types of procedures? Do you need to integrate this technology into your practice? Count on us. Check out our CAD/CAM solutions here.