CAD (computer-aided design) technology has transformed how dental labs create high-precision, customized prosthetics, crowns, bridges, and other elements. However, CAD quality is not without challenges, and common mistakes can directly impact the functionality, fit, and durability of prostheses. If not addressed, these errors can lead to dissatisfaction for both the lab and the patient. Partnering with a specialized CAD design provider not only helps minimize these issues but also offers a significant advantage for labs aiming to deliver top-tier quality.

Below, we’ll explore some of the most frequent errors in dental CAD design and how a specialized partner can be essential in preventing them.

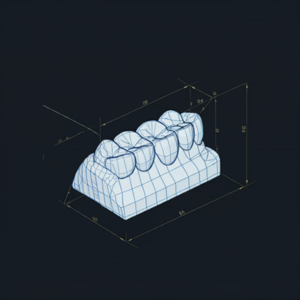

1. Precision issues in scanning and digitization

The dental CAD design process starts with scanning the treatment area and digitizing it—a crucial step for achieving accurate designs. However, the first errors can arise in this phase if the scan isn’t performed correctly. Inaccuracies here—due to movements during scanning, outdated equipment, or poor technique—can result in poorly fitting designs that cause discomfort or functional issues with the final prosthetic. An experienced partner understands the importance of a high-precision scan and can provide guidance on advanced techniques and proper tools to ensure a reliable design foundation.

2. Compliance with format standards and compatibility (STL Format)

The STL format is essential in dental CAD design, ensuring compatibility between design software and manufacturing or 3D printing systems. However, STL files can present common defects like open surfaces or poorly generated meshes, complicating or even preventing the correct fabrication of the piece. A skilled partner reviews and fine-tunes these technical details so STL files meet quality standards, making production easier for the lab.

3. Accurate design of prosthetic margins

One of the common issues in prosthetic design is incorrect margin configuration. Proper margins are vital, as crowns or bridges with poorly designed edges will not securely fit the tooth, leading to discomfort and sealing issues. A specialized dental CAD team understands these clinical parameters and ensures the design meets specifications, providing a secure and proper fit for the patient.

4. Control of occlusion and contact parameters

In CAD design, occlusion and proximal contact are also crucial considerations. These factors affect not only the patient’s comfort but also the prosthesis’s functionality and longevity. If these parameters are improperly configured, the patient may experience discomfort, and the prosthesis may wear prematurely or impact the temporomandibular joint (TMJ). Calibrating these aspects precisely, drawing on expertise in dental anatomy, ensures an ideal fit for the prosthesis—something expert partners are well-equipped to handle.

5. Inadequate insertion path

The insertion path is the angle or direction needed for the prosthesis to fit correctly without compromising stability or causing discomfort. Errors in this setup can lead to prosthetics that shift or even detach under pressure. This aspect requires a detailed analysis and careful adjustment to guarantee the prosthesis is stable and easy to place, preventing issues during placement or prolonged use.

6. Lack of customization to the patient’s morphology

Every patient has unique dental morphology, and designs that don’t account for these individual characteristics may result in uncomfortable or unnatural prosthetics. CAD designs lacking adequate customization can lead to costly adjustments and wasted time, impacting both the lab and the patient. An experienced CAD design partner tailors each design to the patient’s unique features, optimizing both the prosthesis’s aesthetics and functionality, minimizing the need for additional adjustments.

7. Insufficient quality control and final validation

Quality control is a critical step in the dental CAD process, ensuring the final product is error-free before it moves to manufacturing. A lack of rigorous review or a structured validation system can lead to issues that are only detected once the prosthesis is in use. A reliable partner implements comprehensive quality control processes, reviewing every aspect of the design and addressing any imperfections before giving the green light for production, which avoids setbacks and ensures high final quality.

8. Use of outdated technology

CAD technology advances quickly, and relying on obsolete software and tools can limit design quality while making the process slower and less efficient. For many labs, updating software and training staff may require significant time and financial investment. A partner, however, invests in cutting-edge technology and continuous team training, allowing the lab to benefit from the latest innovations without directly shouldering these costs. This also ensures the partner stays current with best practices in design and production within the sector.

For dental labs, choosing the right CAD design partner significantly impacts the efficiency, precision, and quality of their services. From the initial stages of digitization to the final validation of the design, common errors can be avoided with the support of an expert partner who not only brings specialized knowledge in advanced software and techniques but also enables the lab to optimize resources and improve the patient’s experience.

Investing in a reliable CAD design partner is ultimately an investment in patient satisfaction and the dental lab’s reputation. With the right support, labs can ensure they deliver high-quality products that meet each patient’s needs and expectations, making the CAD design experience truly effective and satisfying for all parties involved.